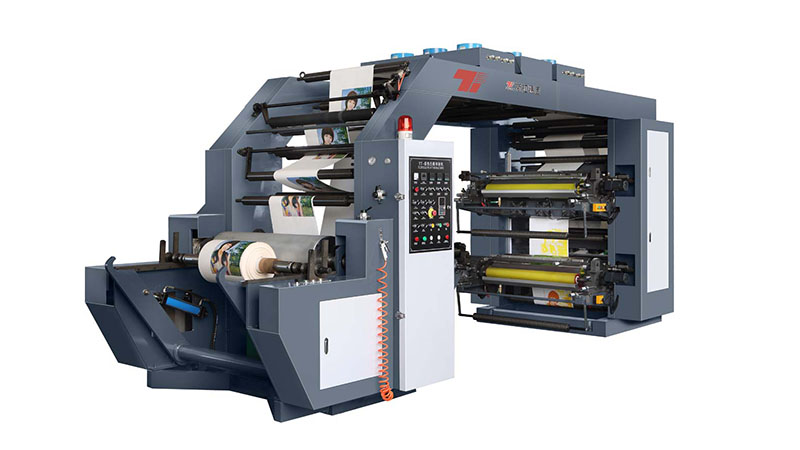

Flexographic printing machine, also called aniline press which uses photosensitive resin plate as the printing plate of printing machine. It adopts environmental ink and has advantage of low edition-producing cost , this is an ideal machine for mass lots , large variety production manufacturer It is also suitable for printing HDPE, LDPE, paper, rolling paper etc.

Parameters And Main Parts Introduction

|

Max.Width of Substrate |

600 |

800 |

800 |

|

Max.Pringting Width(mm) |

560 |

760 |

760 |

|

Printing materials |

20-350g paper and film |

||

|

Printing Speed(n/min) |

120m/min |

120m/min |

120m/min |

|

Plate thickness |

1.7-3.4 |

1.7-3.4 |

1.7-3.4 |

|

Weight of machine |

5000 |

5500 |

6000 |

|

Machine size |

5.4*1.8*2.9m |

5.4*2*2.9m |

5.4*2*2.9m |

1- The machine use synchronous belt working,low noise,And it can usefully control the machine on and off speed change, setting the color be accurate.

2- Machine rewinder is hydraulic and pneumatic control,and with friction winder,Make the material more tight and more smooth.

3- Machine unwinder is with EPC and hydraulic,no need lift the material by manual.

4- Machine is use hydraulic up and down,printing gear is helical gear.

5- Machine is controlled by inverter.

6- Machine speed:120meter/min.Printing speed: 8-100meters /min.

7- The machine will automatic alrm before the machine start.