Full automatic high speed sharp bottom paper bag making machine is suitable for varied primary and printed rolling paper, such as Kraft paper,slick paper,coated paper,medico paper and so on. It finishes all procession all in a time consisting: perforating, middle gluing,printed pattern calibration, tube forming, calibration snapping, bottom folding, bottom forming, and collect final product quantitatively. This machine operate easier, working more efficient, and performance more steadily. It is a fantastic machine for full paper bag, paper bag with window, leisure snack bag, bakery bag, fast food bag, dry fruit bag eco-bag and so on.

Characteristics

1.It is suitable for paper between 40-80gsm.

2.It can change and control bag length through PLC setting.

3.It is with auto tension and EPC system.

Parameters

|

Model |

JYD-850 |

|

|

Length of bag cutting |

|

|

|

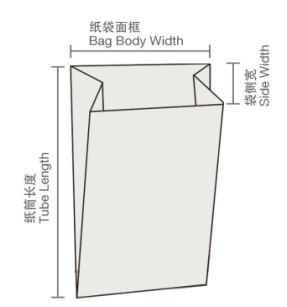

Bag width |

80-350mm |

|

|

Insert size |

20-120mm |

|

|

Bag mouth height |

15/20mm |

|

|

Bag speed |

60-500pcs/min |

|

|

Paper feed width |

1000 mm |

|

|

Paper material dia. |

1000 mm |

|

|

Paper material thickness |

40-80g/m² |

|

|

Working Air |

More than 0.12m3/ minutes, 0.6-1.2 MPa |

|

|

Electric power |

7KW |

|

|

Total weight |

2000kg |

|

|

Machine Dimension |

4600x1950x1700mm |

|

Function Cofiguration

|

1.Paper roll feeding |

|

2.Paper automatic deviation correction(optional) |

|

3.Paper tension self adjustment (optional) |

|

Inline two color printing(optional) |

|

4. Top glue |

|

5. Tube forming |

|

6. Bag tube pulling break |

|

7. Bottom gluing |

|

8.Bottom folding |

|

9.Paper bag collection (batch counting) |